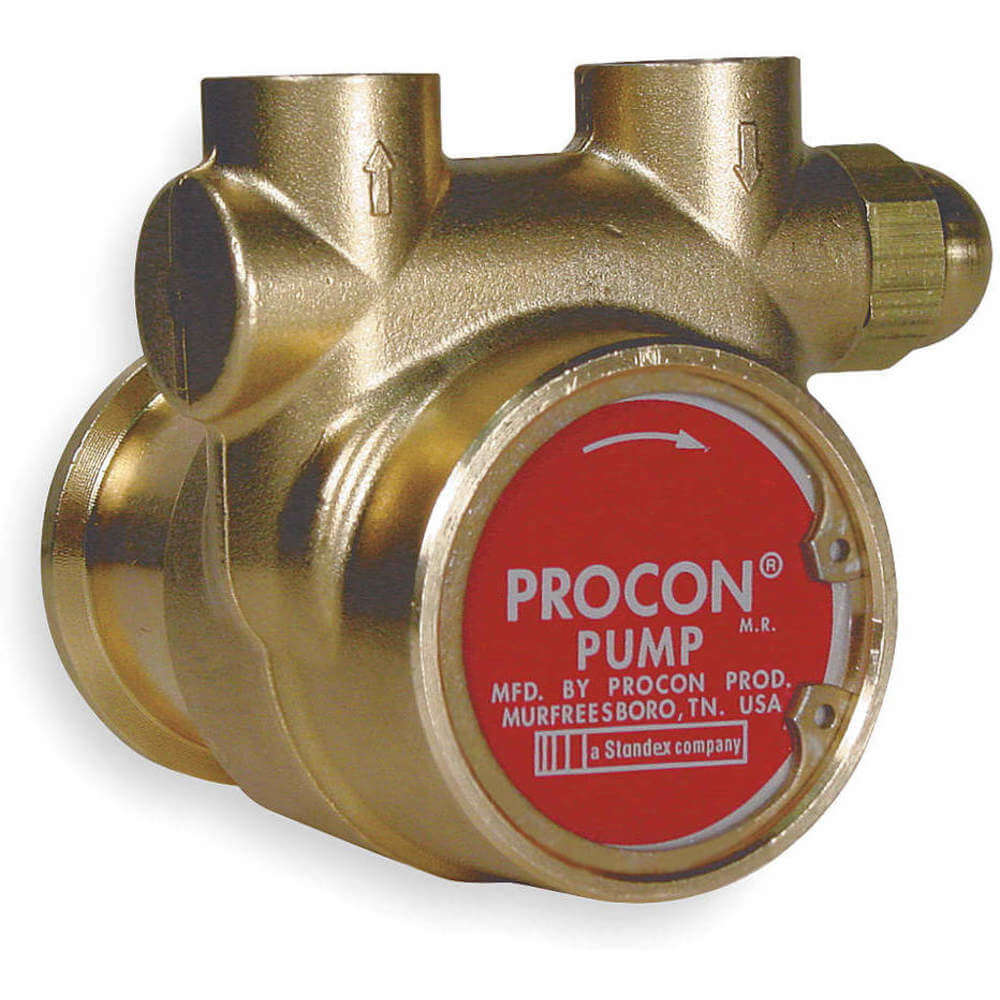

Procon 102E100F11BA rotary vane pump is suitable for beverage dispensing, coffee machines, water purification, cooling systems and industrial fluid transfer applications. It operates as a positive displacement pump having vanes on a rotating rotor inside a cylindrical housing. The vane's motion creates a variable chamber, drawing fluid into the pump's suction side and compressing it through the outlet. It ensures a consistent flow, self-priming ability & flexibility to handle various liquids & gases effectively.

Working Mechanism:

- Inside a rotary vane pump, a rotor spins within a cylindrical casing, pushing the vanes outward to create a vacuum that draws fluid or gas from the inlet into the expanding space.

- Subsequently, the vanes retract, compressing the fluid or gas before it gets expelled through the outlet.

- This seamless cycle of suction, compression and discharge guarantees a continuous and steady flow of fluids or gases within the pump.

Features:

- It has a robust brass construction, making it durable & corrosion-resistant and features a 3/8 inch NPT port threaded for easy installation.

- This pump features a flow rate of 100 GPH or 300 LPH and has EPDM / nitrile elastomer seals for a reliable & effective sealing mechanism.

- It offers a bolt-on mounting type for secure attachment and has a single flat drive configuration for efficient operation.

- This pump features a non-balanced ceramic / carbon seal type for leakproof operations.

- It has a clockwise rotation, allowing for precise fluid control and offers internal components made of carbon for long-lasting reliability.

Compatible Accessories:

- Procon 1113 V-band clamp: It provides a secure connection between cylindrical components, ensuring a dependable & tight seal across various applications.

Frequently Asked Questions:

Q. What factor should I consider while selecting this rotary vane pump?

A. Major factors include pumping speed, ultimate vacuum, fluid compatibility and environmental considerations.

Q. How do I maintain this rotary vane pump?

A.

- Regularly inspect the pump for signs of wear, leaks and damage.

- Keep the pump and its surroundings clean to prevent debris from entering.

- Replace worn-out vanes, seals and gaskets to maintain proper functioning.

- Adhere to specified duty cycles to prevent overheating and extend the pump's lifespan.

- Ensure proper tension and condition of belts and pulleys (if applicable).

- Use proper safety procedures during maintenance, including disconnecting the pump from power sources.

Q. What safety considerations should I take when using rotary vane pumps?

A. Safety considerations include proper grounding, venting exhaust gases, operating in well-ventilated areas for flammable or toxic gases and adhering to manufacturer recommendations for safe operation & maintenance.

Q. How do I choose the right rotary vane pump for my application?

A. You can choose the right rotary vane pump for your application by considering flow rate, pressure, material compatibility, vacuum level, operating conditions, size, noise and energy efficiency.

Q. What is the difference between oil-lubricated and oil-free rotary vane pumps?

A. Oil-lubricated rotary vane pumps use oil for sealing, lubrication and cooling, offering higher vacuum levels, whereas oil-free vane pumps use self-lubricating materials or alternative sealing methods to prevent oil contamination.

Q. How do I prevent oil backstreaming in a rotary vane pump?

A.

- Use gas ballast for moist or condensable vapours.

- Operate within recommended temperature limits.

- Regularly check and change pump oil.

- Choose the correct pump oil type.

- Consider installing a cold trap.

- Maintain the pump regularly.

Change Country

Change Country

Trade pricing is available for

Trade pricing is available for  Order Value should be £500+

Order Value should be £500+