Height Under Clamp Arm

Clamp Arm Length

Get it by Monday, Apr 28

£19.99 Flat Shipping + VAT £19.99 flat shipping is applicable on orders with an aggregate weight less than 10kg. Orders exceeding 10kg will be charged default shipping rates

Payment

Delivery

Step 1 Add the items into your cart or submit a Purchase order

Step 2 Checkout, select NET30 payment (provide company registration and VAT number)

Step 3 Delivery via TNT or Royal Mail and receive invoice for payment in 30-days

Step 4 Make payment via BACS to our factoring partner,

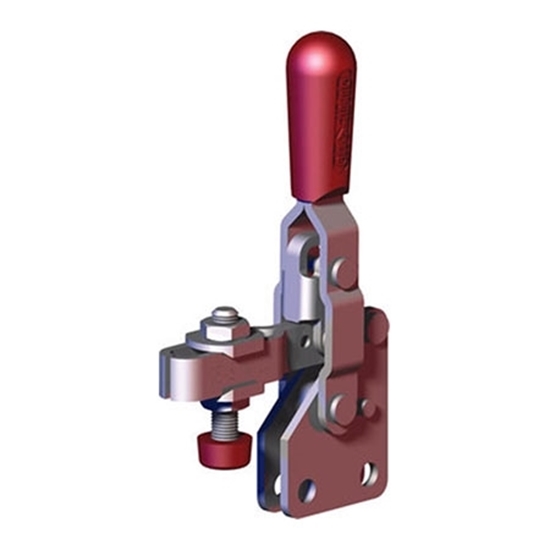

| Item | Vertical Hold Down Clamp |

| Base Mounting Centers | 0.63 x 0.94" |

| Clamp Arm Length | 1.02" |

| Clamp Arm Style | U-Bar |

| Clamp Bar Opening | 100 Deg. |

| Diameter | 0.170" |

| Handle | Vertical |

| Handle Opening | 55 Deg. |

| Height Under Clamp Arm | 0.62" |

| Holding Capacity | 125 Lbs. |

| Material | Stainless Steel |

| Mounting Base | Flange |

| Overall Height | 3.080" |

| Overall Length | 2.040" |

| Spindle | Flat Cushion Neoprene |

| Thread Size | 10-32 |

| Toggle Lock Plus | No |

| Type | Vertical Handle Hold Down, Stainless Steel |

| Ship weight (kg) | 0.07 |

| Ship height (cm) | 4.32 |

| Ship length (cm) | 15.24 |

| Ship width (cm) | 4.32 |

| HS code | 8205700090 |

| Country of Origin | US |

Destaco 201-USS vertical toggle clamp holds workpieces firmly in a stationary position using a lever handle that engages & releases the clamping head while pushing it to the upright position. It applies downward clamping force by increasing the applied load through toggle mechanisms and comes integrated with precisely machined components having hardened & ground pivot pins and bushings for prolonged service life. This vertical hold down toggle clamp offers a stationary alternative to removable C clamps or spring clamps while securing material to a work surface. It comes equipped with a long handle providing excellent hand clearance that can be repositioned to limit the opening angle up to 100 degrees for additional safety. This clamp features a fixed design for securing and loosening materials without moving the clamp and has a flanged base with threaded holes for easy installation. Destaco 201-USS vertical toggle clamp is ideal for checking fixtures, light machining, assembling, testing, welding, drilling, milling and woodworking, in the automotive, aerospace, consumer goods and food & packaging industries. It features stainless steel construction for resisting corrosion on exposed surfaces and is capable of withstanding loads up to 125 lb. This vertical toggle clamp has a U bar clamp arm for easy attachment of arm extensions.

Destaco 201-USS vertical toggle clamp offers a broad combination of features, making it suitable for applications such as fixture checking, light machining, assembling, testing, welding, drilling, milling and woodworking in the aerospace, automotive and food & packaging industries.

A. Destaco vertical hold down clamps are specially designed for holding the workpiece stationary against a flat surface / workbench for various industrial applications like woodworking & metalworking.

A. The toggle clamp actuates against the workpiece and compresses or stretches the equipped linkages to keep the workpiece in a stationary position.

A. The holding force or the holding capacity signifies the clamp's capability to hold down the equipment or sheet metal on the assembly line or during other manufacturing processes.

A. A coupling grease like Mobil XTC should be used when dealing with Destaco mechanical clamps, while the Magnalube G grease is great for use with pneumatic cylinder seals.

A. The difference lies in the positioning of the clamp handle when the clamp is in the locked position. A vertical clamp handle is positioned vertically (perpendicular to the base) when in locked position, while in the case of a horizontal toggle clamp, it is positioned horizontally (parallel to the base).

| Product | Model | Height Under Clamp Arm | Clamp Arm Length | Holding Capacity | Toggle Lock Plus | Material | Mounting Base | Clamp Arm Style | Handle | Price | |

|---|---|---|---|---|---|---|---|---|---|---|---|

|

201-U | 0.63" | 1.03" | 100 Lbs. | No | Steel | Flange | U-Bar | Vertical | £18.59 | |

|

201-UB | 0.88" | 1.03" | 100 Lbs. | No | Steel | Straight | U-Bar | Vertical | £24.14 | |

|

201-TU | 0.63" | 1.01" | 100 Lbs. | No | Steel | Straight | U-Bar | T-Handle | £40.27 |

Contact your account manager right away to get personal advice.

We're available Monday through Friday, from 07:30 until 17:00.