Height Under Clamp Arm

Clamp Arm Length

Get it by Thursday, Apr 24

£19.99 Flat Shipping + VAT £19.99 flat shipping is applicable on orders with an aggregate weight less than 10kg. Orders exceeding 10kg will be charged default shipping rates

Payment

Delivery

Step 1 Add the items into your cart or submit a Purchase order

Step 2 Checkout, select NET30 payment (provide company registration and VAT number)

Step 3 Delivery via TNT or Royal Mail and receive invoice for payment in 30-days

Step 4 Make payment via BACS to our factoring partner,

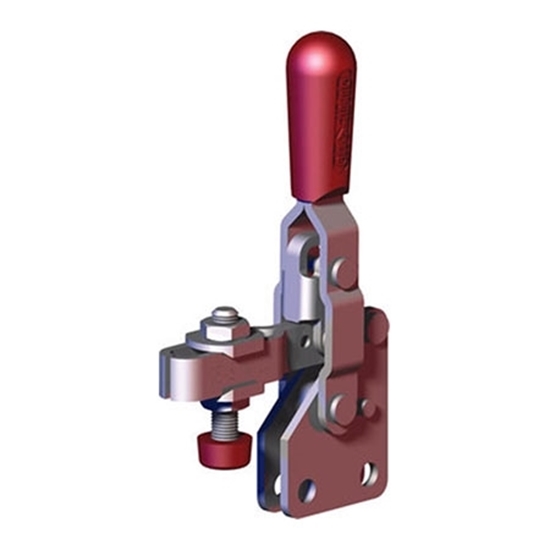

| Item | Vertical Hold Down Clamp |

| Bar Width (in.) | 0.31" |

| Base Length | 1" |

| Base Width | 1.34" |

| Clamp Arm Length | 1.01" |

| Clamp Arm Style | U-Bar |

| Clamp Bar Opening | 100 Deg. |

| Handle | T-Handle |

| Handle Opening | 55 Deg. |

| Handle Style | T-Handle |

| Height Under Clamp Arm | 0.63" |

| Holding Capacity | 100 Lbs. |

| Material | Steel |

| Mounting Base | Straight |

| Overall Height | 3.08" |

| Overall Length | 2.040" |

| Toggle Lock Plus | No |

| Ship weight (kg) | 0.09 |

| Ship height (cm) | 3.51 |

| Ship length (cm) | 4.45 |

| Ship width (cm) | 2.21 |

| Country of Origin | US |

Vertical hold down clampsfeature a straight / T handle positioned perpendicular to the base in locked position to push the clamping arm or the attached spindle against the workpieces. These clamps accommodate spindles for preventing workpieces from loosening or slipping and keeping them stationary throughout the operation. These toggle clamps are a suitable choice for operations requiring repeated clamping or detaching of the workpieces. Destaco 201 Series vertical hold down clamps are used to hold workpieces against flat surfaces in woodworking, light machining, assembly, fixture checking, testing & closure operations. These clamps are the smallest series of the Destaco's vertical hold down clamps to save space during installations and operations. They are equipped with U shaped clamping bars that enable quick spindle adjustments along the holding bar lengths. These U bar clamps allow the users to adjust the toggle clamps according to various sized workpieces. Destaco 201-TU manual toggle clamp has steel construction for structural rigidity and minimising damage / wear due to abrasive conditions. It has a T shaped handle to provide grip while holding. This clamp has a flanged base with threaded mounting holes for quick installation / removal on a flat, horizontal surface / workpiece. It has steel construction for ensuring long life and minimising damage / wear against abrasive conditions & heavy duty use. Raptor Supplies also offers these clamps in variants having stainless steel construction, straight base and straight vertical handle for ease of use in applications of varying requirements.

A. In addition to this variant having flanged base & T handle, Raptor Supplies also offers straight base & straight handle (Destaco 201-UB) and flanged base & straight handle (Destaco 201-U) style vertical clamps as well. For more variants related to Destaco 201-TU clamp, visit Destaco 201 Series clamps page on our website.

A. The holding force or the holding capacity depicts the clamp's ideal capability to hold down equipment or sheet metal on assembly lines or during similar manufacturing processes.

A. The difference lies in the orientation of the clamp handle when the clamp is in the locked position. A vertical clamp handle is vertically oriented (perpendicular to the base) when in locked position, while in the case of a horizontal toggle clamp, it is horizontally oriented (parallel to the base).

A. Certain U bar style clamps, such as Destaco 201-TU, feature a flat tip bonded neoprene spindle that is manually operated using a vertical handle / lever. This handle movement pushes the spindle against the workpiece and prevents it from moving mid operation, thereby ensuring secure clamping.

A. Whenever you're dealing with the brand's mechanical clamps, it is recommended to use a coupling grease like Mobil XTC.

A. Yes, carbon steel clamps from Destaco are zinc plated for withstanding & minimising wear against harsh industrial environments. For applications that require clamping in outdoor conditions, stainless steel variants are also available.

| Product | Model | Height Under Clamp Arm | Clamp Arm Length | Holding Capacity | Toggle Lock Plus | Material | Mounting Base | Clamp Arm Style | Handle | Price | |

|---|---|---|---|---|---|---|---|---|---|---|---|

|

201-U | 0.63" | 1.03" | 100 Lbs. | No | Steel | Flange | U-Bar | Vertical | £18.59 | |

|

201-USS | 0.62" | 1.02" | 125 Lbs. | No | Stainless Steel | Flange | U-Bar | Vertical | £42.65 | |

|

201-UB | 0.88" | 1.03" | 100 Lbs. | No | Steel | Straight | U-Bar | Vertical | £24.14 |

Contact your account manager right away to get personal advice.

We're available Monday through Friday, from 07:30 until 17:00.