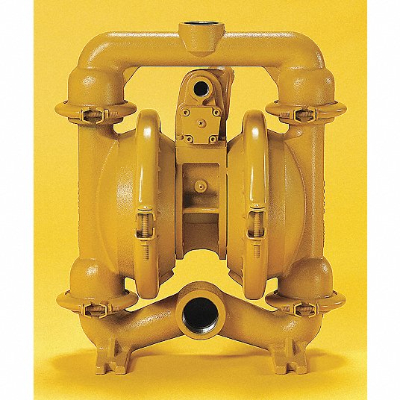

FUSION Technology

Versamatic FUSION Technology features an oversized integrated plate on the diaphragm for supporting it throughout its dynamic motion. The deflection ridges eliminate the chances of radial cracking and flex points. Their backup ribs guide and support the pump's diaphragm with each flex. These diaphragms have no centre hole, ensuring leakage-free operation and installation.