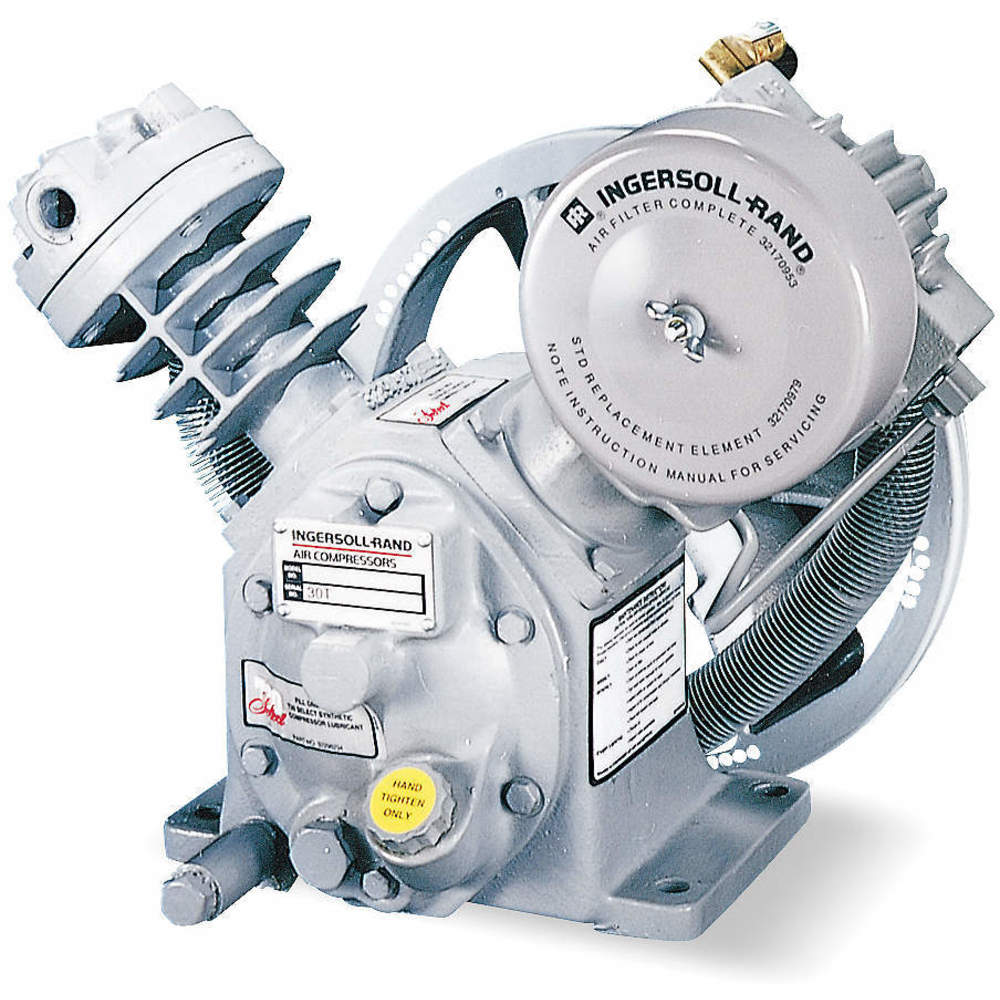

Ingersoll Rand 2545 air compressor pump is designed for powering a two stage reciprocating air compressor that is used for providing high pressure air output. This air compressor pump is ideal for body & machine shops, automotive servicing, fleet maintenance, woodworking, production & manufacturing lines, dry cleaning, farming and general maintenance applications. This air cooled compressor pump features overhung crankshaft, individually cast cylinders and one piece connecting rod for minimising & simplifying the maintenance requirement. It features cast iron construction that offers high durability and ensures over 15000 hours of problem free operation. In contrast to petroleum based lubricants, this pump features synthetic lubricant for increasing the pump's efficiency while minimising the damage against high temperatures.

Ingersoll Rand air compressor pump's V shape design features finned cylinders for increasing the pump cooling in closed off environments. It has a finned copper intercooler that increases the pump's efficiency while lowering the operating temperature. Ingersoll Rand 2545 air compressor pump has high efficiency finger valves that provide high pressure & consistent air delivery throughout the operation. This air compressor pump offers a magnetic starter which provides a safe way for starting the motor under load. Its oversized industrial grade bearings minimise the friction, thereby extending the pump's durability.

Uses:

Ingersoll Rand 2545 air compressor pump is suitable for driving reciprocating air compressor. This system runs air powered tools and pneumatic equipment for various applications. Various operations in body & machine shops, automotive servicing, fleet maintenance, woodworking, production & manufacturing lines, dry cleaning, farming and general maintenance are supported by this compressor pump. Ingersoll Rand air compressor pump is also suitable for powering automated machinery and cutting equipment.

Working Mechanism:

- Ingersoll Rand 2545 air compressor pump works by forcing the air into the container and then pressurising it.

- After the pressure builds up inside the tank, the air is forced through an opening or a nozzle.

- This air output is then used to power various pneumatic tools and equipment in industrial facilities and maintenance shops.

Features:

- This Ingersoll Rand 2545 air compressor pump features cast iron construction, making it suitable for various continuous-duty applications.

- It comes with simple splash lubrication to ensure that the pump is easy to maintain & requires minimum maintenance.

- This air compressor pump has high-efficiency finger valves to provide consistent air delivery throughout the operation.

- It features stainless steel reed valves to ensure increased volumetric efficiency.

- This Ingersoll Rand model 2545 offers individually cast cylinders and an overhung crankshaft for durability and has a one-piece connecting rod for ensuring easy maintenance.

- It has a V-shape design and finned cylinders to ensure that the heat generated from the pump operation is easily dispersed through radiation.

Compatible Accessories:

- Air compressor controller: Ingersoll Rand air compressor control system is suitable for controlling Ingersoll Rand 2545 air compressor pump. This programmable control system improves the efficiency of the air compressor system by driving the control of the pump.

- Compressor oil: Ingersoll Rand compressor oil is suitable for maintaining peak performance for air compressor units at a range of temperatures. This compressor oil offers high thermal conductivity and compressor efficiency while minimising frequent maintenance & downtime. Ingersoll Rand compressor oil offers upto 8000 hours of trouble free run time.

- Compressor air filters: Ingersoll Rand compressor air filters are designed to filter the intake air that passes through the air compressor. Filtered out air prevents any chances of dust / dirt accumulation inside the compressor tank.

Standards and Approvals:

Ingersoll Rand 2545 air compressor pump is manufactured in compliance with ASME standards.

Installation:

Ingersoll Rand 2545 air compressor pump is installed onto the compressor tank. This pump is bolted onto the flat plate that is welded onto the compressor tank and the output air line is connected to the compressor cylinder. The compressor pump is connected to the motor using belts.

Frequently Asked Questions:

Q. What safety precautions should be taken while handling Ingersoll Rand 2545 air compressor pump?

A. Few safety precautions are required to be followed while using the Ingersoll Rand 2545 air compressor pump:

- The compressor should be connected to a properly grounded circuit before usage to eliminate the chances of any electrical hazards.

- Do not remove, bypass or modify the safety / relief valves and safety machine guards.

- User should check for air leaks before deploying the air compressor pump.

- Pressure switch should not be adjusted to exceed the maximum discharge pressure.

- User should disconnect the input power before conducting any maintenance task on the unit.

- Inspect the drive belts before starting the pump. User should adjust the tension of the drive belts, if necessary.

- Check for unusual vibrations & noise for preventing any machinery damage & harm to user.

Q. What is the difference between Ingersoll Rand 2 stage & variable speed compressor?

A. Ingersoll Rand 2 stage compressor unit compresses the air incrementally, in stages, whereas for variable speed compressor, the air compression rate changes as the speed of the motor vary.

Q. Can Ingersoll Rand air compressor be left pressurised?

A. Yes, the storage tank of the air compressor can be left pressurised over long durations for regular use, else keep drained if not in use for a longer period.

Q. Does the brand offer air compressors in other variants?

A. Ingersoll Rand air compressors are available in a variety of variants, such as rotary screw, portable gas engine and stationary gas engine air compressors on Raptor Supplies.

Q. Why does Ingersoll rand 2545 air compressor get hot?

A. During air compression, the air gets hot due to heat of compression. In case the air compressor is not fitted with an after cooler, the storage tank gets hot during the air compression.

Q. Can an air compressor tank be welded?

A. Yes, the air compressor tank can be welded for maintenance & repair purposes.

Change Country

Change Country

Trade pricing is available for

Trade pricing is available for  Order Value should be £500+

Order Value should be £500+