JUN-AIR Compressors

In contrast to traditional compressors, JUN-AIR compressors are free from piston rings. This feature reduces the tolerance between the compressor cylinder and piston, thereby minimising energy loss and heat development.

The brand's extensive catalogue includes piston air compressors, pressure & vacuum switches, rotary vane compressors / vacuum pumps and vacuum generators. Gast 1-stage air compressors have permanent oil-less lubrication to release clean air and hot dog tanks that soften bursts of air from the back-and-forth compressor for consistent airflow. They come with an automatic start / stop pressure switch, beginning the compressor at 30 / 70 / 80 psi and stopping at 50 / 100 psi. These air compressors feature a manual drain, pressure safety valve, pressure gauge and globe valve for control, safety and longevity.

See More

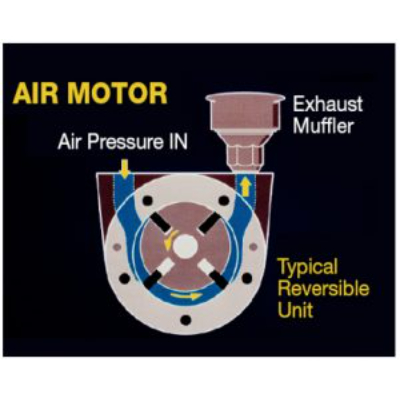

Air MotorsGast air motors are ideal for various hand-held tools, such as sanders, drills, grinders and nut runners. They offer no-load speeds up to 3000 rpm and are available in shaft diameters ranging between 3/8 and 1 inches.(52 Products)

Rotary Vane Compressor/Vacuum PumpGast 1 / 3-phase compressors/vacuum pumps are ideal for continuous-duty applications like vacuum forming, circulation therapy and pond aeration. They feature self-lubricating and self-adjusting sealed bearings & vanes to ensure a pulse-free airflow.(27 Products)

Diaphragm Compressor/Vacuum PumpGAST Diaphragm Compressor / Vacuum Pumps are suitable for applications requiring a continuous-duty performance and moderate pressure supply, such as filling gas cylinders and hydrogenation of edible oils. They feature reversible, 1/8 and 1/4 inch inlet and outlet ports for easy installation.(20 Products)

Piston Air Compressor/Vacuum Pump(62 Products)

Stationary Electric Air Compressors(5 Products)

Vacuum Pumps(3 Products)

Regenerative Blowers(18 Products)

Pressure and Vacuum SwitchesStandard pressure switches ideal for use with Gast air compressors. Feature a diaphragm-type actuation for delivering high output torque at low pressures. Capable of handling temperatures and pressures ranging from -22 to 257 deg F and 5 to 65 psi, respectively (2 Products)

Vacuum Regulators(2 Products)

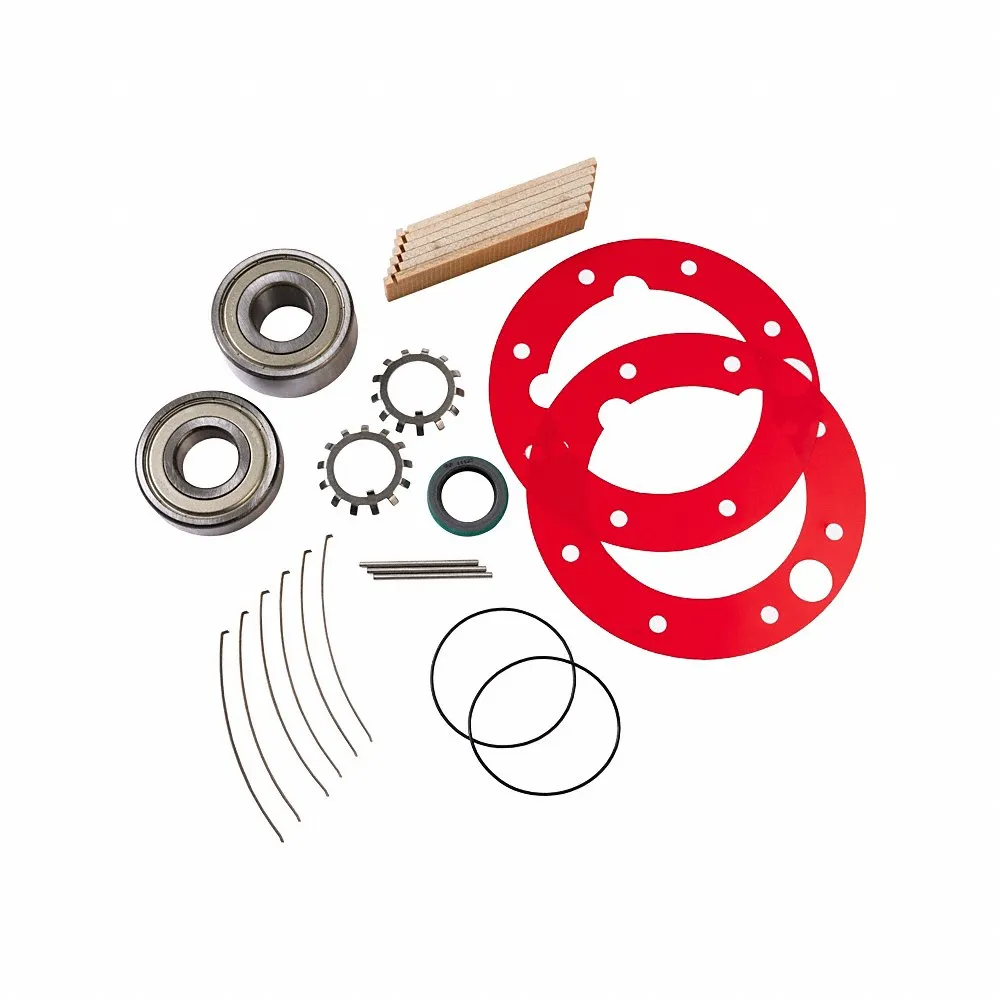

PartsIncludes cooling fans, pressure switches and air motor repair kits ideal for use with Gast compressors and vacuum pumps (12 Products)

Pneumatic Control Accessories(30 Products)

Pneumatic Modular FRL Accessories(1 Product)

Pneumatic Muffler(5 Products)

Vacuum EjectorsGast inline-box vacuum ejectors suck the vapours or gas from pneumatic vessels and conveyor systems. They offer a low-maintenance and noiseless operation due to the absence of moving parts and deliver a maximum speed of 40 rpm.(4 Products)

Engine Specialty Tools(11 Products)

Brackets(1 Product)

Capacitors(1 Product)

Oils(2 Products)

Cylindrical Vibration Isolators(1 Product)

Extension Springs(1 Product)

Vacuum and Pressure Relief Valves(4 Products)

General Purpose Filter Elements(3 Products)

Laboratory Air Compressors(2 Products)

O-Rings(2 Products)

Valve Accessories(2 Products)

Air Compressor Pumps(1 Product)

Bottles and Jars(1 Product)

Compressor Oil(1 Product)

Filter Bags(1 Product)

Filter Cartridges(1 Product)

Intake Filters and Silencers(1 Product)

Oilers and Reservoirs(1 Product)

Pressure and Vacuum Gauges(1 Product)

The brand's extensive catalogue includes piston air compressors, pressure & vacuum switches, rotary vane compressors / vacuum pumps and vacuum generators. Gast 1-stage air compressors have permanent oil-less lubrication to release clean air and hot dog tanks that soften bursts of air from the back-and-forth compressor for consistent airflow. They come with an automatic start / stop pressure switch, beginning the compressor at 30 / 70 / 80 psi and stopping at 50 / 100 psi. These air compressors feature a manual drain, pressure safety valve, pressure gauge and globe valve for control, safety and longevity.

In contrast to traditional compressors, JUN-AIR compressors are free from piston rings. This feature reduces the tolerance between the compressor cylinder and piston, thereby minimising energy loss and heat development.

Gast air motors utilise compressed air for producing rotational motion of the shaft. This air motor technology ensures that there are no electrical sparks & overheating of the unit's components. Gast rotary vane motors having axial vanes are fitted into a slotted rotor, mounted eccentrically with the motor's housing bore. The torque required to dri...

Gast regenerative blowers feature blower technology that supports reacceleration of the blower motor. In operation, the impeller of these regenerative blowers draws air into the compression space through the inlet port. This air is moved radially outward through the curved housing by centrifugal force and supports the succeeding blade for imposing ...

Gast vacuum generators have patented design featuring a combination of no moving parts and a series of venturi nozzles. Each nozzle of these vacuum generators has a progressively larger orifice for extracting maximum energy from the compressed air supply while improving the levels of vacuum generated.

Gast diaphragm compressors work just like standard piston compressors. However, the diaphragm technology minimises the noise & ensures quiet operation as opposed to loud piston compressors. The diaphragm of Gast compressors creates a vacuum as it moves down. This motion pushes the inlet valve to the open position as the outside air is allowed in. A...

From 1921, Gast Manufacturing, Inc. has been a global designer and manufacturer of quality air-moving products. They provide cost effective solutions for a broad range of applications, such as manufacturing, healthcare and environmental cleanup.

Gast Manufacturing, Inc., listed under general-purpose machinery manufacturing industry, is located in Benton Harbor, MI, United States.

Gast pumps and air compressors are used for agricultural foam markers, crop sprayers and pest control equipment. These products are ideal for various industries, such as airbrushes, lab equipment, oil atomizers, food processing and more.

The basic difference between a single and two-stage air compressor is the number of times the air gets compressed. In a single-stage compressor, the air is compressed once. Whereas in a two-stage compressor, it is compressed twice which doubles the air pressure.

A 10 wt detergent oil is suitable to lubricate Gast air motors. However, 10w30 detergent oil can also be used as a substitute.

It is recommended that the size of the air line should be one size larger or of the same size as the port.

Yes, the unique design of the Gast air motor allows the user to install / mount it in any position depending upon the application requirement.

Gast air motor repair kits help to repair the air motors on the spot. These repair kits include motor gaskets, vanes, bearings, filters and motor maintenance manuals.

An eight vane Gast air motor is used in applications that require minimum operating speed, usually for inching applications.

It is recommended that the filters should be cleaned, inspected and / or replaced after 500 hours of operation.

Gast AH255D flushing solvent is suitable for cleaning Gast products. The user should avoid any solvent that contains flammable, electrically conductive or petroleum-based components for cleaning purposes.

Raptor Supplies offers Gast vanes for the brand's scarifiers. These vanes are used for removing coatings, contaminants and imperfections from surfaces, ensuring a smoother and more uniform finish.

Yes, customers looking for Gast spray gun accessories can look for repair kits. These repair kits include bearings, gaskets, pins, seals, springs and vanes that fit into the brand's spray guns when these already installed parts get damaged due to some technical issues.