Mounting Base

Height Under Clamp Arm

Get it by Tuesday, Apr 8

Payment

Delivery

Step 1 Add the items into your cart or submit a Purchase order

Step 2 Checkout, select NET30 payment (provide company registration and VAT number)

Step 3 Delivery via TNT or Royal Mail and receive invoice for payment in 30-days

Step 4 Make payment via BACS to our factoring partner,

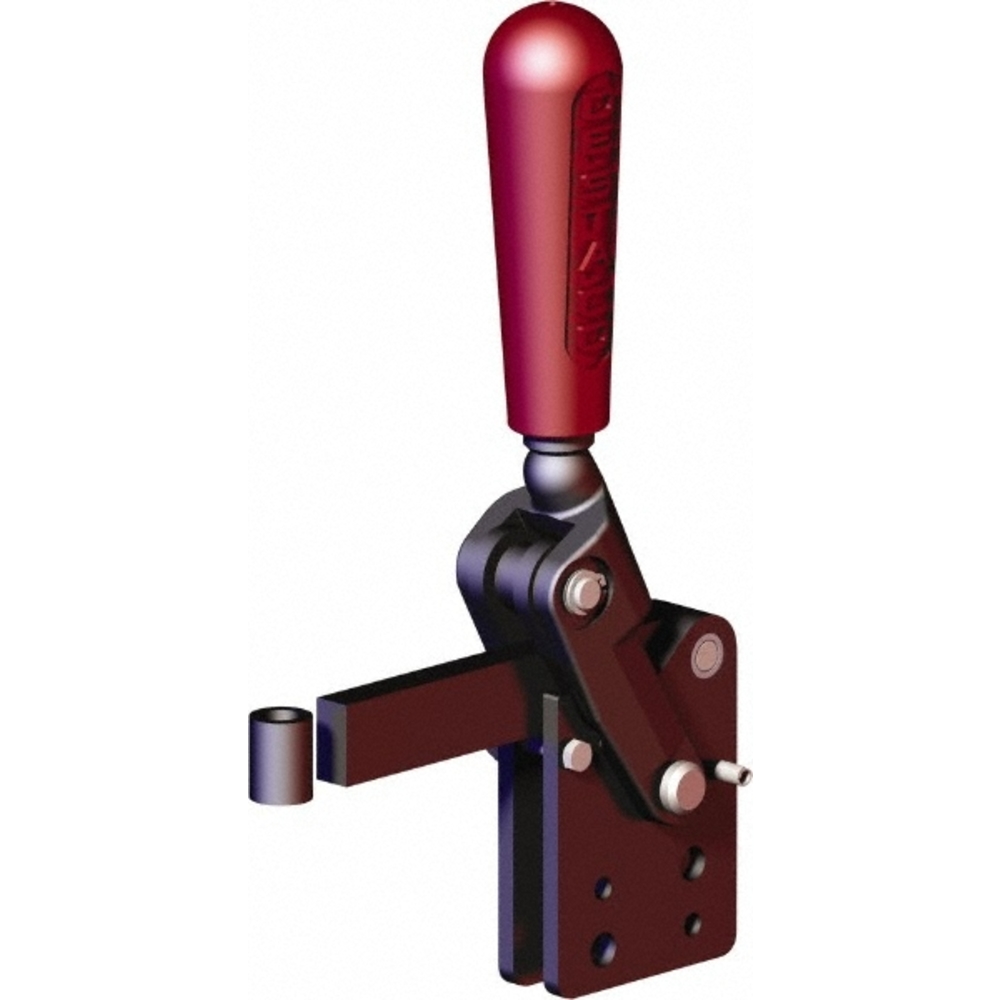

| Item | Vertical Hold Down Clamp |

| Bar Width (in.) | 0.98" |

| Base Length | 2.95" |

| Clamp Arm Length | 3.35" |

| Clamp Arm Style | Long Solid Bar |

| Clamp Bar Opening | 120 Deg. |

| Handle | Vertical |

| Handle Opening | 90 Deg. |

| Handle Style | Straight |

| Height Under Clamp Arm | 2.95" |

| Holding Capacity | 2200 Lbs. |

| Material | Steel |

| Mounting Base | Straight |

| Overall Height | 11.26" |

| Overall Length | 160" |

| Toggle Lock Plus | No |

| Ship weight (kg) | 1.84 |

| Ship height (cm) | 28.6 |

| Ship length (cm) | 16 |

| Ship width (cm) | 5.41 |

| Country of Origin | US |

Vertical hold down clampsfeature a straight handle that is perpendicularly oriented to the base (in locked position) to push the clamping arm or attached spindle against a workpiece. These manual clamps are suitable for operations that require regular clamping & unclamping of same workpiece. Destaco 535 Seriesvertical hold down clamps are ideal for holding down workpieces against flat surfaces during assembly, checking fixtures, welding & heavy duty clamping operations. They have heavy duty steel construction with hardened bushings & pivot pins for reducing wear / tear due to rough usage. These clamps have a maximum holding capacity of 2250 lb. Destaco 535-LB hold down clamp has straight mounting base for installation on lateral vertical surfaces. It has a long solid clamping bar with a bolt retainer for attaching a spindle at a fixed position. This solid bar can also be modified to accommodate diverse application requirements. It is equipped with large bar guides to provide lateral support to the clamp while performing heavy duty applications. Raptor Supplies also offers these clamps in variants having a maximum holding capacity of 1575 lb; flanged base for installation on horizontal surfaces.

Destaco 535-LB vertical hold down clamp is used for checking fixtures, milling, assembly, welding and heavy duty clamping applications in automotive, aerospace, consumer goods, transportation and food & packaging industries.

A. Raptor Supplies offers similar manual clamps having flanged base (535-L) for installation on horizontal surface. For more variants related to Destaco 535-LB clamp, visit Destaco 533 & 535 Series clamps page on our website.

A. Vertical hold down clamps are manually operated using a vertical handle / lever to move the clamping arm or attached spindle against workpieces and prevent them from moving mid-operation for secure clamping.

A. The difference between a vertical & horizontal toggle clamp lies in the locking position of the clamp handle. A vertical clamp handle is vertically oriented or perpendicular to the base when in locked position, whereas the horizontal toggle clamp is horizontally oriented or positioned parallel to the base.

A. The holding capacity or holding force represents the capability of a clamp to hold down mechanical equipment or sheet metal while assembling automotive parts or during manufacturing processes.

A. Clamping force or exerting force denotes the actual force exerted by the clamp onto the workpieces for holding them. The measure of holding force or capacity indicates the ideal strength of the clamp measured during the clamp manufacturing process. The clamping force is generally lesser than the holding capacity due to several factors, such as position of spindle in the clamping bar and the opposing force applied on the clamp.

A. A coupling grease, such as Mobil XTC is recommended for use with the brand's mechanical clamps.

A. Yes, All of the Destaco carbon steel clamps are zinc plated to resist & reduce wear & tear due to harsh industrial environments. Destaco also offers stainless steel clamps for applications requiring clamping in outdoor conditions.

| Product | Model | Base Length | Base Width | Clamp Arm Length | Height Under Clamp Arm | Holding Capacity | Mounting Base | Overall Height | Overall Length | Price | |

|---|---|---|---|---|---|---|---|---|---|---|---|

|

533-LB | 2.36" | - | 2.56" | 2.17" | 1500 Lbs. | Straight | 9.31" | 125" | £165.95 | |

|

533-L | 2.36" | 1.75" | 2.56" | 1.86" | 1500 Lbs. | Flange | 8.6" | 125" | £144.16 | |

|

535-L | 2.95" | 2.13" | 3.35" | 2.63" | 2200 Lbs. | Flange | 10.35" | 160" | £174.08 |

Contact your account manager right away to get personal advice.

We're available Monday through Friday, from 07:30 until 17:00.