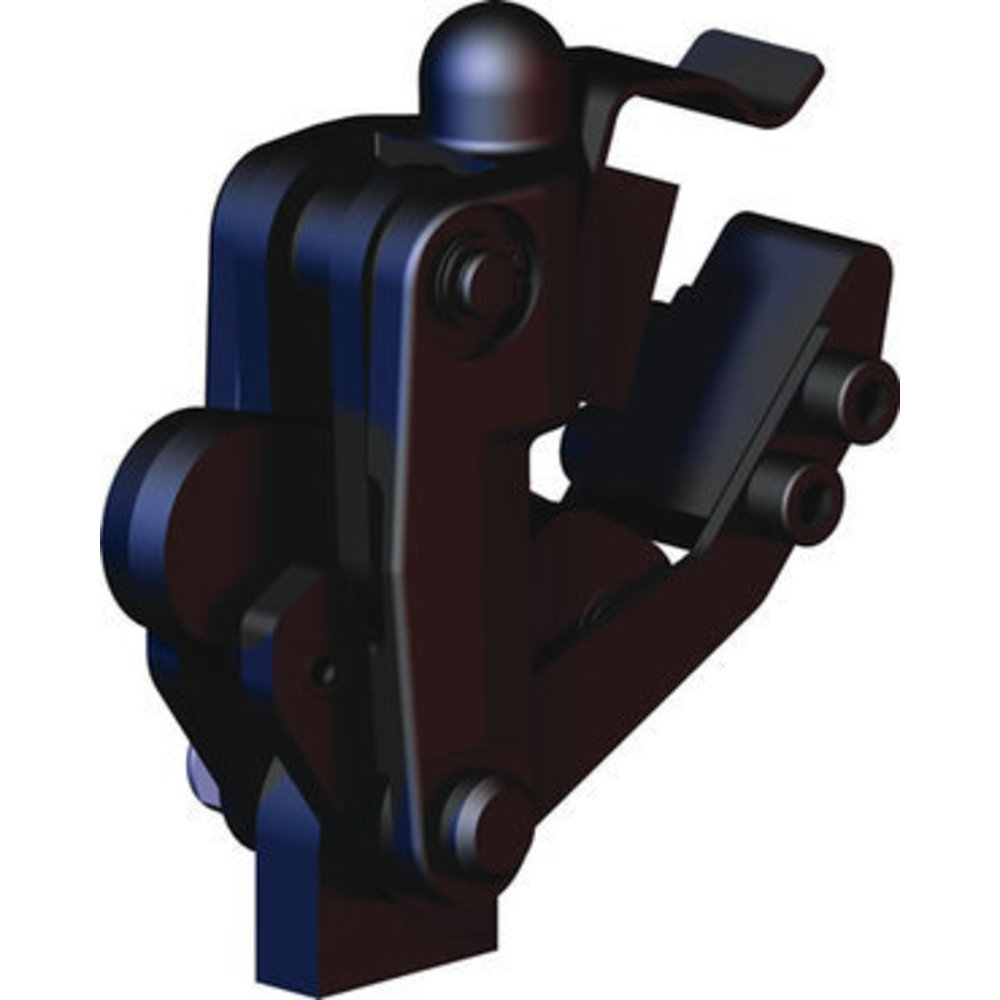

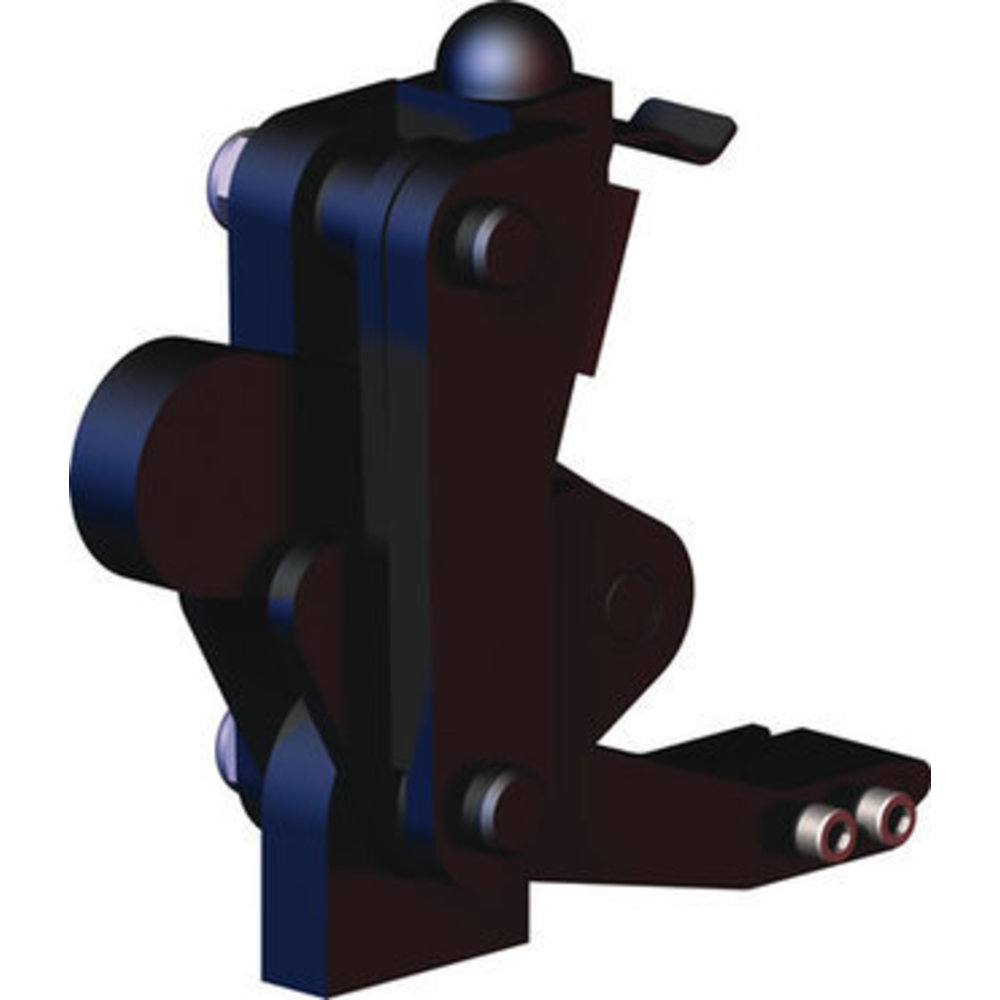

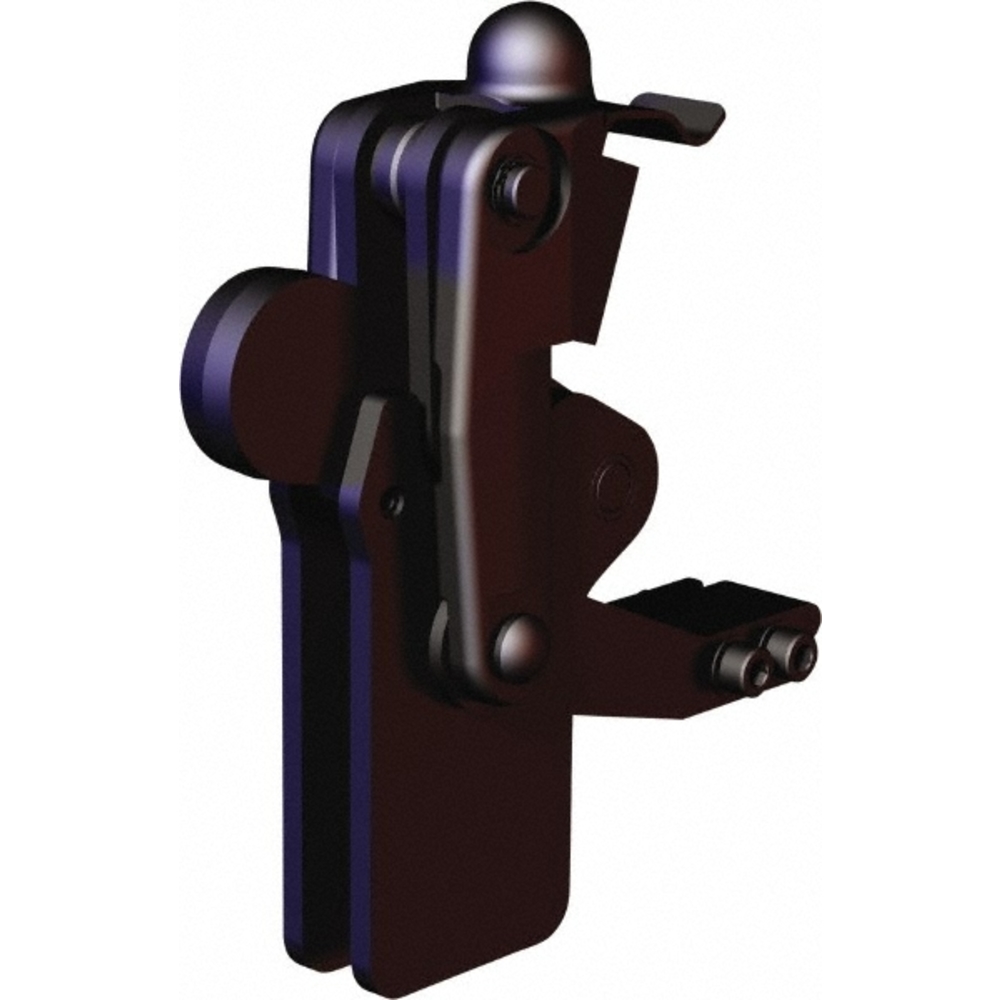

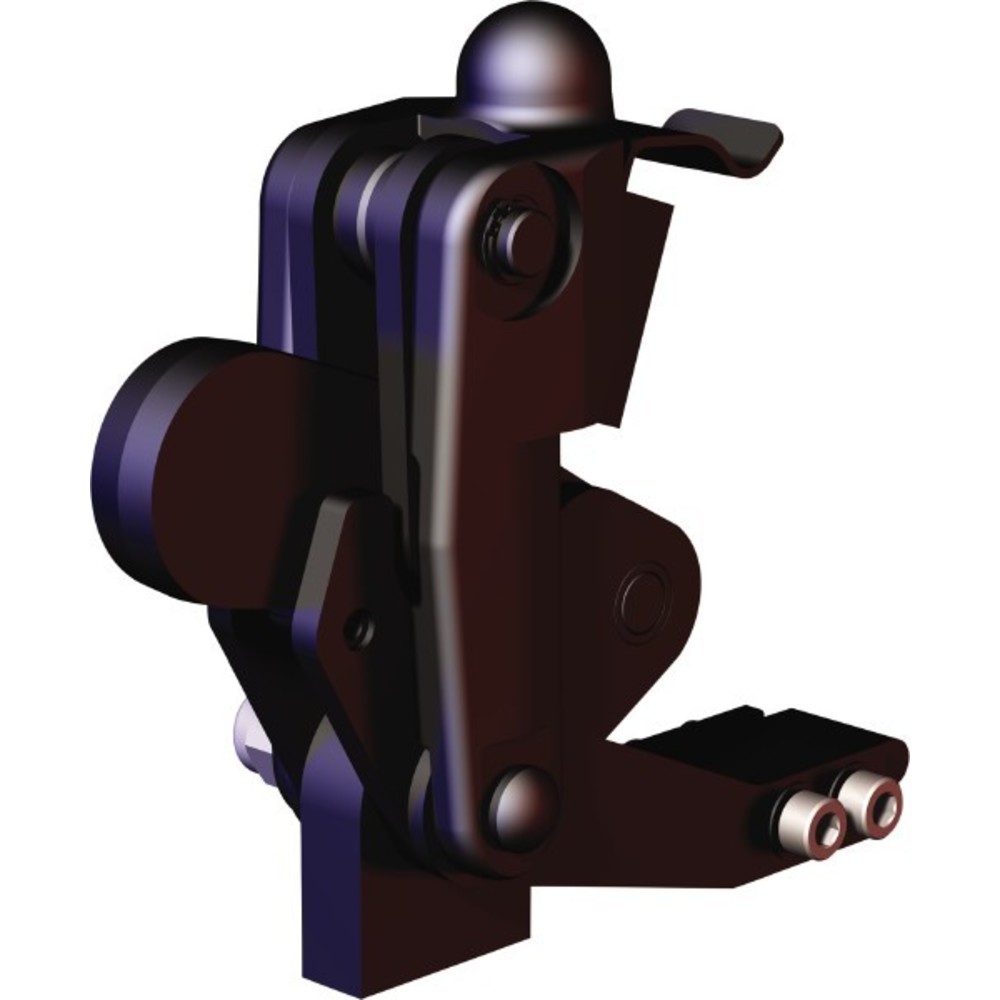

Mounting Base

Clamp Arm Length

Get it by Monday, Apr 28

Payment

Delivery

Step 1 Add the items into your cart or submit a Purchase order

Step 2 Checkout, select NET30 payment (provide company registration and VAT number)

Step 3 Delivery via TNT or Royal Mail and receive invoice for payment in 30-days

Step 4 Make payment via BACS to our factoring partner,

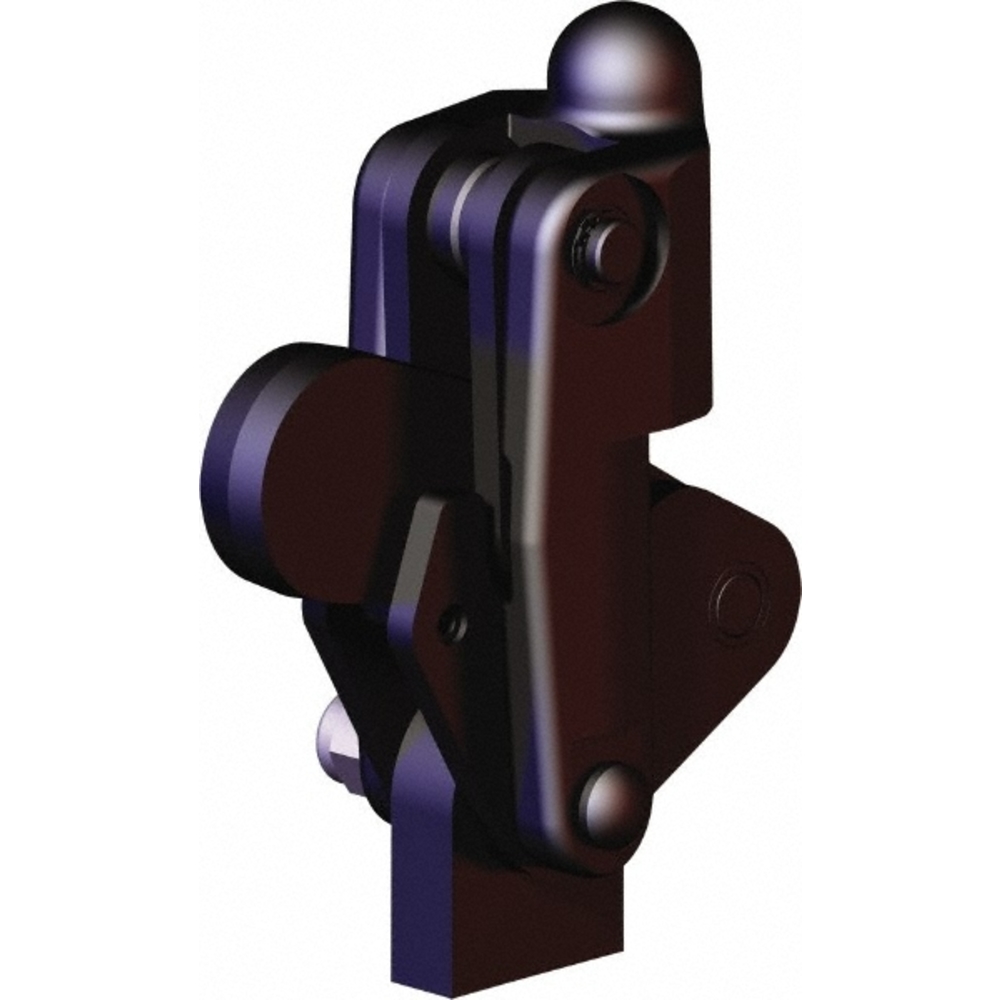

| Item | Vertical Hold Down Clamp |

| Base Length | 1.13" |

| Base Width | 0.51" |

| Clamp Arm Length | 0.56" |

| Clamp Arm Style | Weldable |

| Clamp Bar Opening | 200 Deg. |

| Handle | Vertical |

| Height To Top Of Clamp Arm | 2.44" |

| Holding Capacity | 560 Lbs. |

| Material | Forged Alloy Steel |

| Mounting Base | Long |

| Overall Height | 3.53" |

| Spring Clip | No |

| Toggle Lock Plus | No |

| Ship weight (kg) | 0.2 |

| Ship height (cm) | 2.87 |

| Ship length (cm) | 8.92 |

| Ship width (cm) | 2.77 |

| Country of Origin | US |

Destaco 501-LB vertical hold down clamp is designed for holding large workpieces in manufacturing plants and production line facilities. This hold down action clamp is an ideal choice for operations where there is a requirement to clamp / detach the workpiece repeatedly throughout the operation. Destaco vertical hold down toggle locking clamp's forged alloy steel construction resists bending / breaking under heavy loads. They have modular design that offers flexibility to position the clamp arm, base and handle. It features a weldable clamping arm for secure installation and a bar with an adjustable angle (upto 200 degrees) for clearing the work area. This heavy duty clamp has hardened pivot pins & bushings for minimising clamp wear over intensive usage. However, this clamp is not recommended for woodworking, food & packaging, machining and closure checking applications. Destaco 500 Series clampsare also offered in swivel & long style base options on Raptor Supplies.>

Destaco 501-LB vertical hold down clamp is designed for performing production line clamping, welding, checking fixtures and assembly operations. However, these clamps are not recommended for woodworking, food & packaging, machining and closure checking tasks.

A. Yes, in addition to Destaco 501-LB long base style variant, the brand offers swivel base (Destaco 503-MBLSC & Destaco 505-MB) vertical clamps as well.

A. Clamping force is the amount of force actually applied to a workpiece by closing & locking the clamp. It is normally less than the stated holding capacity. The actual clamping force depends on various factors, such as cylinder bore, cylinder area, spindle position (clamping arm length) and available air pressure. In most cases, the clamping force is approximately 2 to 3 times the force exerted by a pneumatic cylinder.

A. The holding force or the holding capacity depicts the clamp's capability to hold down the equipment or sheet metal on assembly lines or during similar manufacturing processes.

A. Destaco vertical hold down clamps are specially designed for holding the workpiece stationary against a flat surface / workbench for various industrial applications like woodworking & metalworking.

A. The difference lies in the orientation of the clamp handle when the clamp is in the locked position. A vertical clamp handle is vertically oriented (perpendicular to the base) when in locked position, while in the case of a horizontal toggle clamp, it is horizontally oriented (parallel to the base).

A. Vertical clamps feature a solid bar style clamping arm / flat tip bonded neoprene spindle that is manually operated using a handle / lever. This handle movement pushes the clamping arm / spindle against the workpiece and prevents it from moving mid operation, thereby ensuring secure clamping.

A. Whenever you're dealing with the brand's mechanical clamps, it is recommended to use a coupling grease like Mobil XTC.

A. Yes, carbon steel clamps from Destaco are zinc plated for withstanding & minimising wear against harsh industrial environments. For applications that require clamping in outdoor conditions, stainless steel variants are also available.

| Product | Model | Base Length | Base Width | Clamp Arm Length | Height To Top Of Clamp Arm | Holding Capacity | Mounting Base | Overall Height | Spring Clip | Price | |

|---|---|---|---|---|---|---|---|---|---|---|---|

|

503-MBLSC | 1.12" | 0.39" | 0.53" | 2.75" | 1500 Lbs. | Swivel With Locking Spring Clip | 2.75" | Yes | £257.92 | |

|

506-MLBLSC | 2.58" | 1.1" | 1.38" | 6.46" | 5000 Lbs. | Long With Locking Spring Clip | 8.3" | Yes | £288.79 | |

|

506-MBLSC | 1.97" | 0.63" | 1.27" | 4.76" | 5000 Lbs. | Swivel With Locking Spring Clip | 6.59" | Yes | £394.03 | |

|

503-MLBLSC | 1.75" | 1.82" | 0.53" | 3.92" | 1500 Lbs. | Long With Locking Spring Clip | 3.93" | Yes | £382.32 | |

|

505-MLBLSC | 2.09" | 0.88" | 1.14" | 5.29" | 2400 Lbs. | Long With Locking Spring Clip | 6.83" | Yes | £547.56 | |

|

505-MBLSC | 1.38" | 0.48" | 0.99" | 3.89" | 2400 Lbs. | Swivel With Locking Spring Clip | 5.43" | Yes | £172.75 | |

|

505-MB | 1.38" | 0.48" | 0.99" | 3.89" | 2400 Lbs. | Swivel | 5.43" | No | £107.38 |

Contact your account manager right away to get personal advice.

We're available Monday through Friday, from 07:30 until 17:00.