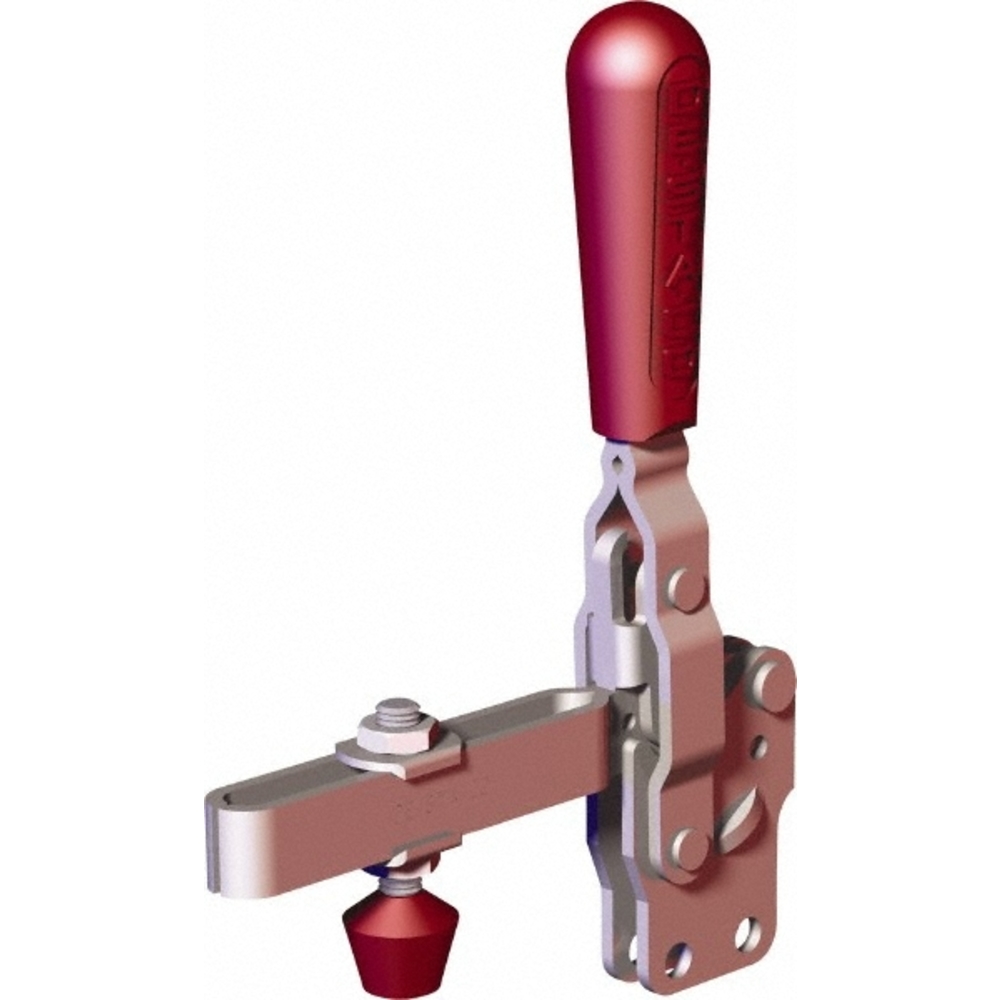

Destaco 207-ULB vertical handle toggle clamp is used in the aerospace, automotive and food & packaging industries for woodworking, light machining and fixture checking. It provides a stationary alternative to removable spring clamps or C clamps while securing materials to the work surface. It is integrated with precisely machined components having hardened & ground pivot pins and bushings for prolonged service life. This toggle clamp has a fixed design for securing and loosening materials without moving the clamp and features a flanged base with threaded holes for easy installation. This vertical hold down clamp features steel construction for structural rigidity and resisting corrosion on exposed surfaces. This vertical hold down clamp allows bar and handle opening angles up to 99 and 57 degrees, respectively. This vertical toggle clamp provides the flexibility to position the base, handle & clamp arm and weld them in the desired position for different clamping applications. Destaco 207-ULB vertical hold down clamp is integrated with an ergonomically designed handle to reduce strain and pain while working. The lever handle engages & release the clamping head, which holds a workpiece onto a worktable.

Uses:

Destaco 207-ULB vertical hold down clamp is used in the automotive, aerospace and food & packaging industries for woodworking, light machining and fixture checking.

Features:

- Destaco 207-ULB vertical hold down clamp features steel construction for structural rigidity and corrosion resistance.

- This vertical hold down clamp is equipped with a neoprene spindle to ensure toughness and maximum clamping force.

- Destaco 207-ULB vertical hold down clamp comes integrated with an ergonomic handle grip for anti slip performance.

- This vertical hold down clamp allows bar and handle openings up to 99 and 57 degrees, respectively.

- This vertical hold down clamp is capable of withstanding loads up to 375 lb.

Compatible Accessories:

- Destaco 225208-M: This flat tip bonded neoprene spindle is compatible with a variety of Destaco clamps including 207-U, 207-UR, 207-UL, 207-UB, 207-ULB, 207-UF, 227-U, 227-UB, 225-U, 225-UR, 225-UB and 817-UE. This spindle can be adjusted for accommodating materials of varying thicknesses and can be replaced for extending the service life of toggle clamps by reducing the risk of marring when rubber stoppers start to wear away. The flat tip spindle is oil resistant & LABS free. This spindle includes jam nuts for quick and secure clamping as well as to allow adjustments between clamping distance. It is capable of being operated at temperatures ranging from -22 to 212 degrees Fahrenheit.

Standards and Approvals:

- Destaco 207-ULB vertical hold down clamp is manufactured in accordance with international standards like ISO 9001:2015 & ISO 14001:2015 and ensures good environmental health, user safety and enhanced performance of the clamp.

Installation:

- Destaco 207-ULB vertical hold down clamp has a flanged base having threaded holes for ease of installation

Frequently Asked Questions:

Q. What is a vertical hold down clamp?

A. Destaco vertical hold down clamps are specially designed for holding the workpiece stationary against a flat surface / workbench for various industrial applications like woodworking & metalworking.

Q. How do you adjust a vertical hold down toggle clamp?

A. After clamping, the clamping force can be adjusted by loosening / tightening the spindle nut.

Q. What is the difference between a vertical & horizontal toggle clamp?

A. The difference lies in the positioning of the clamp handle when the clamp is in the locked position. A vertical clamp handle is positioned vertically (perpendicular to the base) when in locked position, while in the case of a horizontal toggle clamp, it is positioned horizontally (parallel to the base).

Q. What does holding capacity mean in terms of clamps?

A. The holding force or the holding capacity signifies the clamp's capability to hold down equipment or sheet metal on the assembly line or during similar manufacturing processes.

Q. What does clamping force mean?

A. Clamping force is the amount of force actually applied to a workpiece by closing & locking the clamp. It is normally less than the stated holding capacity. The actual clamping force depends on various factors, including cylinder bore, cylinder area, spindle position (clamping arm length) and available air pressure. In most cases, the clamping force is approximately 2 to 3 times the force exerted by a pneumatic cylinder.

Q. Which grease is ideal for Destaco clamps for their rebuilding?

A. A coupling grease like Mobil XTC should be used when dealing with Destaco mechanical clamps, while the Magnalube G grease is great for use with pneumatic cylinder seals.

Q. What is the significance of the red colour of the handle of Destaco clamps?

A. There is no such significance of colour of the clamp's handle, as it only represents a recognisable area. This helps operators in finding the handle quickly & easily.

Q. Does Destaco supply water resistant clamp sensors?

A. Yes, Destaco also supplies inductive sensors designed in accordance with IP65 standards to ensure protection from powerful hydraulic jets, dust & heavy rain.

Q. Does Raptor Supplies offer replacement spindles for hold down clamps?

A. Yes, Raptor Supplies provides Destaco spindles for hold down clamps, to replace worn out units and protect them from damage caused by abrasion / twisting / flexing.

Q. What variants of Destaco vertical handle toggle clamps are available on Raptor Supplies?

A. Destaco vertical handle toggle clamps are available in steel, stainless steel and forged alloy steel variants.

Change Country

Change Country

Trade pricing is available for

Trade pricing is available for  Order Value should be £500+

Order Value should be £500+