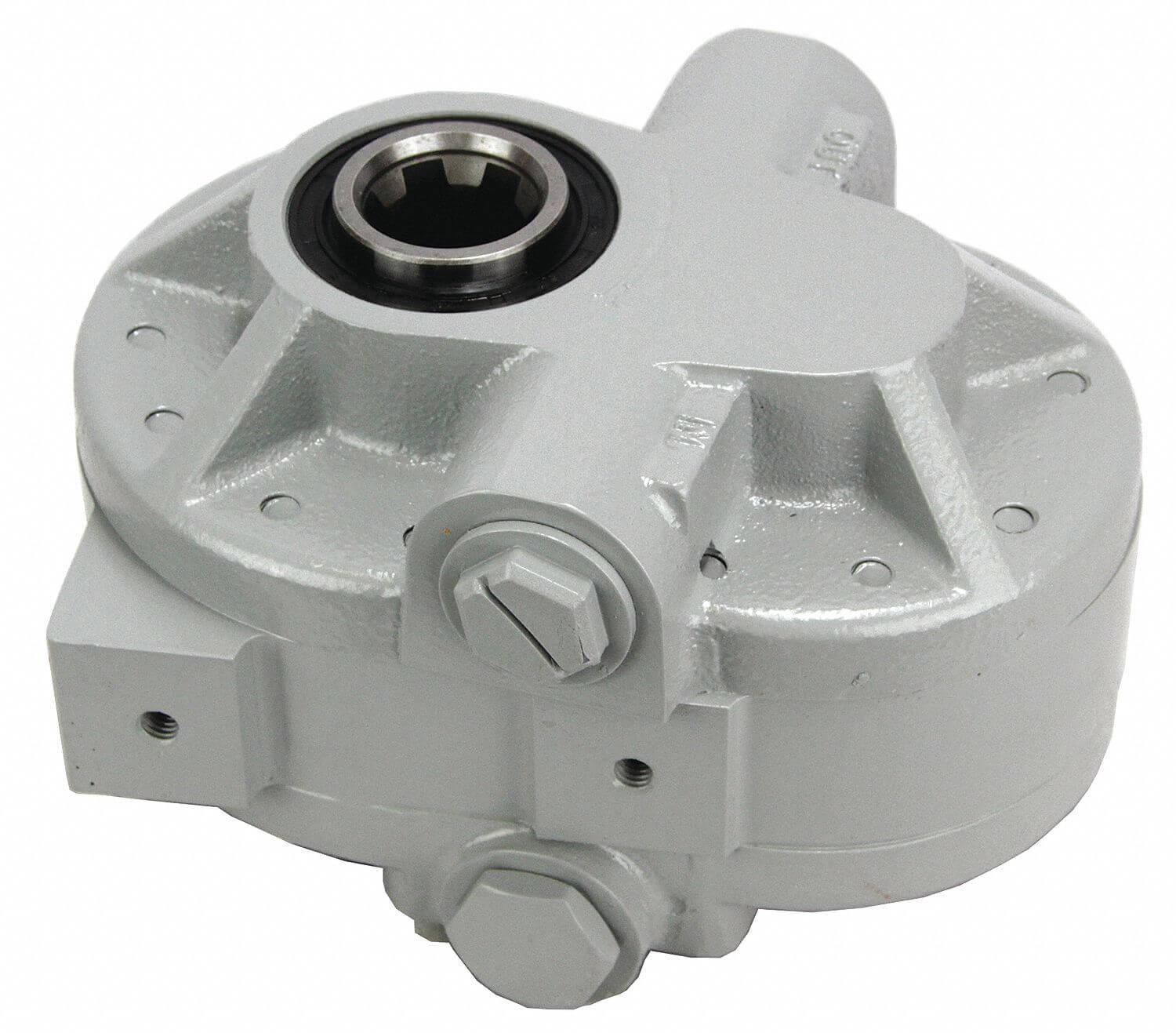

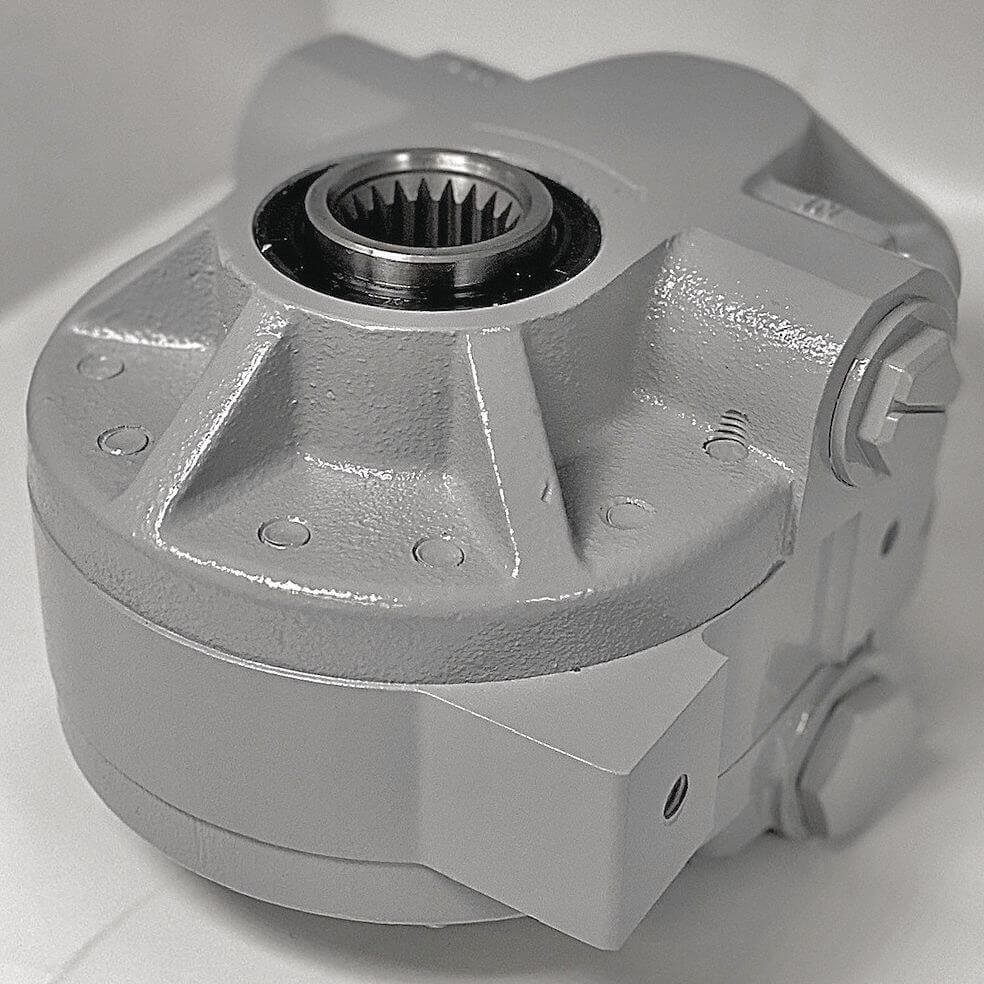

Chief GP-PTO-A-9-6-S hydraulic PTO pump connects to a vehicle's or machinery's power take-off (PTO), converting mechanical energy from the engine into hydraulic power. It's employed to operate hydraulic systems that control lifting, lowering and steering functions. It is ideal for agricultural machinery, such as tractors, combines and harvesters, in construction equipment like cranes, loaders and excavators.

Working Mechanism:

- Chief GP-PTO-A-9-6-S hydraulic PTO pump utilises the engine power of tractors or vehicles to drive its internal components.

- As the engine transfers the power through the power take-off (PTO), the pump's input shaft rotates, creating a suction that draws hydraulic fluid from a reservoir.

- This fluid is then pressurised within the pump's chambers before being expelled through the discharge connection.

- This process converts mechanical energy into hydraulic pressure, enabling the pump to power hydraulic tools or systems effectively.

Features:

- This hydraulic PTO pump has a maximum flow rate of 21 gallons per minute.

- It has a displacement per revolution of 9.76 cubic inches to facilitate hydraulic fluid delivery with each rotation.

- This hydraulic PTO pump can operate at pressures up to 2500 pounds per square inch (psi).

- It is equipped with a 540 RPM motor speed to deliver power while maintaining efficiency.

- This hydraulic PTO pump is designed for clockwise rotation for seamless integration into existing machinery setups.

- It features a 1-3/8 inch shaft outer diameter.

Frequently Asked Questions:

Q. How do I maintain these hydraulic PTO pumps?

A. Regular maintenance is crucial for hydraulic PTO pumps to ensure peak performance and durability. Start with routine fluid checks to maintain proper lubrication and cooling. Inspect seals, fittings and hoses for wear or damage, addressing issues promptly to prevent fluid loss. Periodic seal inspections and replacements maintain effective sealing while preventing leakage. Regularly clean external surfaces and cooling fins to prevent buildup that can hinder performance.

Q. How do I select the right hydraulic PTO pump for my equipment?

A. Selecting the right hydraulic PTO pump involves key considerations for compatibility and performance optimisation. Start by assessing your hydraulic system's flow rate requirements to match or slightly exceed your equipment's demand for fluid volume. Evaluate both the pump and machinery's operating pressure specifications to prevent overload and ensure alignment. Consider factors like horsepower requirements, shaft size and rotation direction for seamless integration. Prioritise compatibility by verifying connection sizes, shaft configurations and mounting options.

Q. What safety precautions should I follow when operating a hydraulic PTO pump?

A. Operating hydraulic PTO pumps demand strict adherence to safety protocols to prevent accidents, injuries and equipment damage. Ensure proper installation and secure mounting, preventing vibration or detachment. Use appropriate PPE like gloves and eye protection when handling fluids. Follow manufacturer guidelines for startup, shutdown and operation to prevent overloading or system failures. Avoid tampering with safety features and regularly inspect hoses and fittings for wear. Also, train personnel on safe practices, emergency procedures and hazards associated with pump operation.

Change Country

Change Country

Trade pricing is available for

Trade pricing is available for  Order Value should be £500+

Order Value should be £500+