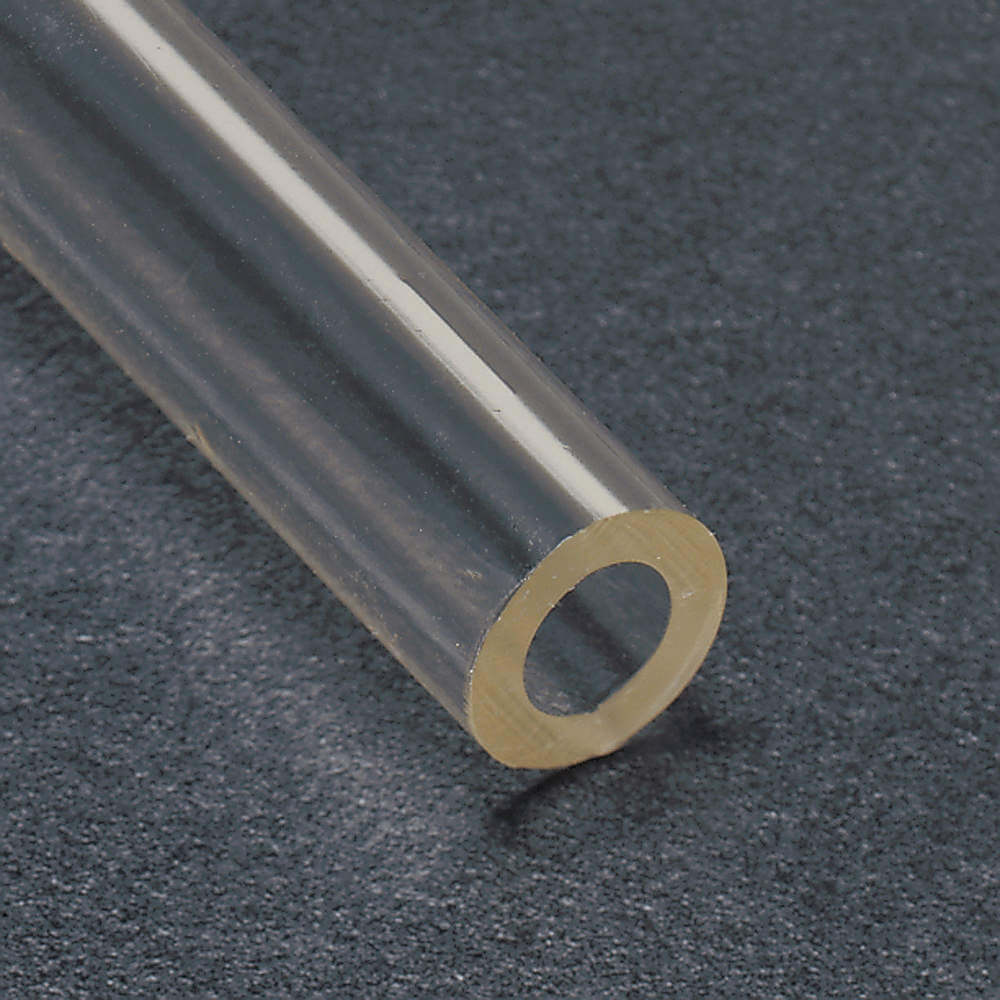

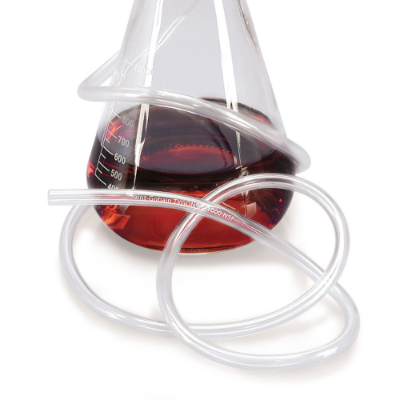

S3TM E-3603 non-DEHP Laboratory Tubing

These non-toxic & non-contaminating tubes are ideal for condensers, desiccators, incubators, drain lines and gas lines. They provide the longest flex life of any clear Tygon tubing and minimise downtime due to pump failure. They are BPA or phthalate-free and feature bio-based formulation to reduce e...