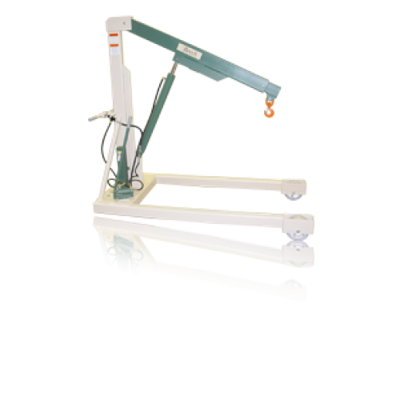

Materialift Vertical Reciprocating Conveyors

Beech Design & Manufacturing's Materialift conveyors are designed to lift & transport heavy loads such as steel beams and pipes in factories, warehouses and construction sites. They meet or exceed the requirements of ANSI / ASME B20.1 and OSHA. These Materiallift conveyors are available in mechanica...